Case Study: QC Apps for Global Leading Fashion Brand and Chain Stores

BUSINESS BACKGROUND

- Headquarter : California, USA, with 10+ Worldwide Merchandising Offices in Mexico, China, Thailand, Indonesia, Pakistan, Bangladesh, Taiwan, Hong Kong

- 300+ Garment Suppliers in US, European and Asia Countries

- 50+ In-House and Outsourcing Garment Inspectors

- 800-1,000 Fashion Styles and Sales Orders Per Month

- 2,000 – 3,000 QC Reports Per Month

- Centralised IT Team focus in Network Infrastructure

GAP in Existing Quality Control Processes

- Quality Control Process is Manual and Data Sharing is Slow!

- Quality Control Reports for Customers are Handwritten and in Basic EXCEL format, Data Presentation and Result Interpretation are Not Systematic!

- Inspectors Spend Too Much Time (Normally ½ day) to Prepare QC Reports with 100+ Images after On-site Inspection!

- Customers Complain on QC Reports, Frequent Delays and Inconsistent!

- Managers Being Chased Constantly on Decisions, External and Internal!

- QC Analysis Reports Preparation Time is 1 week to 10 days!

- QC Changes Tedious to Upgrade, Implement and Ramp In!

TARGET RESULTS

- Save Time: Increase Daily Productivity of Inspectors and Reduce Data Entry and Manipulating Time!

- Strengthen Process: Standardize QC Checkpoints, Defect Codes, Early Alerts, etc!

- Real Time Reports: QC Reports are Ready Real Time for Suppliers, Customers and Managers!

- Big Data Availability: All Historical QC Data are Accessible 24/7, so are the Analysis & Trend KPI Reports!

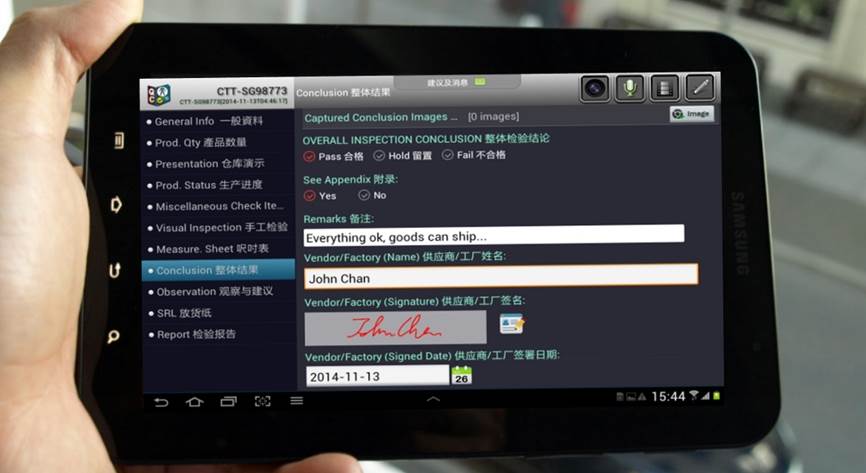

TOOL â CLOUDQCAPPS (Operation)

FINAL RESULTS & BENEFITS for CUSTOMERS

- Report Automation on Various Reports Over 2000/month

- QC Reporting Time Reduces from Average 90 mins to 30 secs

- Intelligent Big Data Analysis During Off Work Hours

- Strengthen Workflow and Eliminate Human Input Problems

- Reduce Staff Training Effort, Improve their Confidence

- Do ONCE : No Data Re-input to avoid Human Errors

- Save QC Time and Cost

- QC Inspectors – QC Productivity Increased Significantly

- QC Manager – Accurate KPI Reports created within 15 mins

- Resource Planning and Assessments

- People – QC Staff Workload Scheduling and Performance Assessments

- Contractors – Analysis on Defects Pattern and Failures Trend, Allowing

Tight and Precise Quality Assurance on Inbound Services and Supplies

Customer Feedback : QC Department Costs Reduced by 33% !!